THIN CUTTING FRAME SAW

MADE IN TAIWAN

SPECIFICATIONS:

| Main Motor | 20HP |

| Cooling Blower | 2HP |

| Feed speed | 0.2~1.5M/min |

| Number of stroke | 480 times/min |

| Cutting width Max. | 160mm |

| Cutting height (automatically control by digital display) | 60~250 mm |

| Kerf loss | 1.25~1.4 mm |

| Stroke of frame | 210mm |

| Length of timber At least | 300 mm |

| Wood height tolerance | ±0.5 mm |

| Min. lamella thickness | 2.0 mm |

| Cutting accuracy | ±0.1mm |

| Compress air | At least 6 bar, 87 pei |

| Suction performance per port | 30m/min, 1300 meter/hr |

| Suction tubes | 5*D100mm |

| Blade grinding time | 15~25times |

| Blade regrinding time hardwood | 4-6hr/ softwood 8-10hr |

| Max. number of saw blades | 25pcs |

| Machine dimensions (LxWxH) | 3400 mm×1300 mm×2300 mm |

| Packing dimensions (LxWxH) | 3500 mm×1300 mm×2300mm |

| Net weight/ Gross weight | 2600 kgs/3000kgs |

HEAVY DUTY VERTICAL BAND SAW

MADE IN TAIWAN

SPECIFICATIONS:

| FE-700 | FE-700D | |

| Min. cutting thickness | 3mm | |

| Distance from fence to blade | 185mm | |

| Distance from feed roller to blade | 190mm | |

| Height from the floor to table | 835mm | |

| Wheel diameter | 710mm (28”) | |

| Wheel width | 90mm (3-1/2”) | |

| Width of blade | 100mm (4”) | |

| Length of blade | 4850mm | |

| Feed speed | (Variable) | |

| Wheel drive motor | 20HP | |

| Hydraulic pump motor | 2HP | |

| Net / Gross weight | 1600kgs / 1800kgs | 1700/ 1900 Kgs |

| Packing dimensions | L228 x W138 x H225cm |

DOUBLE MITER SAW

MADE IN TAIWAN

SPECIFICATIONS:

| FE-12 | FE-160 | |

| SUITABLE FOR 45 DEGREE CUTTING FOR WOODEN & PLASTIC MOULDINGS PNEUMATIC CLLAMPING | ||

| MAX. CUTTING WIDTH: | 80 MM | 160 MM |

| MAX. CUTTING HEIGHT | 75 MM | 75 MM |

WOODEN FRAME JOINER

MADE IN TAIWAN

SPECIFICATIONS:

| PNEUMATIC CLAMPING | |

| PNEUMATIC NAILING | |

| WORKING WIDTH: | 6-100MM |

| V-NAIL LENGTH | (7)8/10/12/15 MM |

| V NAIL WIDTH | 10.5 MM |

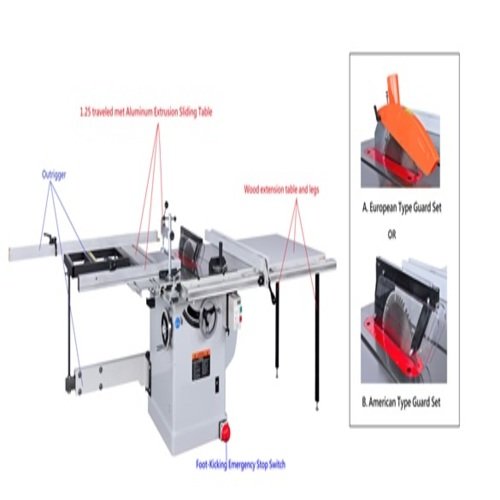

TILTING ARBOR TABLE SAW

MADE IN TAIWAN

SPECIFICATIONS:

| SAW BLADE: | 305 MM |

| POWER: | 5 HP |

| WITH AMERICAN TYPE FENCE & 680 mm RAIL ALUMINIUM EXTRUSION SLIDING TABLE : | 1200 X 230 MM |

| OUTRIGGER FOOT KICKING EMERGENCY STOP | |

MOULDING BRUSH SANDER

MADE IN TAIWAN

SPECIFICATIONS:

| Max. working width | 12" (300mm) |

| Max. working height | 4” (105mm) |

| Min. Work-pieces length | 15" (380mm) |

| Optional short hold down roller Min work piece length | 190mm |

| Min. Work-pieces thickness | 3/8" (9.5mm) |

| Feed speed adjustment by VFD (inverter) | 2– 12 m/min |

| Speed of Sanding Wheel | 200 – 1200 RPM |

| Top brushing head motor | 2 x 3HP |

| Conveyor motor | 1/2 HP |

| Machine Dimension (D × W × H) | 122cm × 93cm × 125cm |

| Packing Dimension (D × W × H) | 138cm × 108cm × 146cm |

| Net weight | 470 KGS |

| Gross weight | 500 KGS |

FOUR SIDE MOULDING SANDER

MADE IN TAIWAN

SPECIFICATIONS:

| REGULAR | (HEAVY BASE) | |

| Max. working width | 12” (300mm) | 12” (300mm) |

| Max. working height | 4” (100mm) | 4” (100mm) |

| Min. work-pieces length | 33” (838mm) | 33” (838mm) |

| Min. work-pieces thickness | 3/8” (9.5mm) | 3/8” (9.5mm) |

| Feed speed | 2.8 – 8.2 m/min (Verious speed pulley drive) | 2 ~ 12 m/min (Inverter) |

| Speed of sanding head | 200-1200 RPM | 200-1200 RPM |

| Top sanding head motors | 2 x 3/4HP (0.55 KW) | 2 x 3/4HP (0.55 KW) |

| Bottom sanding head motor | 1 x 3/4HP (0.55 KW) | 1 x 3/4HP (0.55 KW) |

| Right sanding head motor | 1 x 1/2HP (0.37 KW) | 1 x 1/2HP (0.37 KW) |

| Left sanding head motor | 1 x 1/2HP (0.37 KW) | 1 x 1/2HP (0.37 KW) |

| Angle sanding head motor | 1 x 1/2HP (0.37 KW) | 1 x 1/2HP (0.37 KW) |

| Conveyor motor | 1/4 HP (0.18KW) | 1/4 HP (0.18KW) |

BRUSH SANDING TOOLS

MADE IN TAIWAN

SPECIFICATIONS:

| Length of Sanding Head | 60mm | 152mm |

| Diameter of Sanding Head | 188mm ~ 268mm | 188mm ~ 268mm |

| No. of sanding strip + wooden brush | 18 pcs | 18 pcs |

DRUM SANDER

MADE IN TAIWAN

SPECIFICATIONS:

| Max. working width | 25” (635mm) | 25” (635mm) |

| Max. working height | 4” (100mm) | 4” (100mm) |

| Table dimension | 635 x 870mm (25"x 34 1/4") | 635 x 870mm (25"x 34 1/4") |

| Sanding wheel diameter | 150mm (6") | 150mm (6") |

| Speed of sanding wheel | 1720 RPM | 1720 RPM |

| Feeding speed | 3.7M / min (12FPM) | 2.4~7.2M / min (8~24FPM) by pitch pulley |

| Sanding motor | 5HP | 5HP |

| Feeding speed | 1/4HP | 1/4HP |

| Machine Dimensions (L x W x H) | 37" x 41" x 43" | 37" x 41" x 43" |

| Packing Dimensions (L x W x H) | 41" x 45" x 45" | 41" x 45" x 45" |

| Net weight | 380 KGS (838lbs) | 380 KGS (838lbs) |

| Gross weight | 430 KGS (948lbs) | 430 KGS (948lbs) |

CNC ROUTER

MADE IN TAIWAN

Description of Goods:

| (USA) Tigertec 408AD Dual Spindle CNC ROUTER. - 3D computerized routing system - AC servo motors on all axis - Work area1250X2540X200 mm. - High precision planetary gear boxes on X and Y axis - Preloaded backlash-free balls screw on Z axis - Z stroke 200 mm - Y axis clearance 200 mm - Travel Speed 60M/Min |

Manual Spindle 7 KW, HSD -Italy -2 Nos:

| -Connection type: Collet ER32 -Rated voltage: 380V -Rated speed: 12.000 rpm -Max speed: 18.000rpm -Rotation: Right -Manual Tool Change -Max tool dia. 16mm -Ceramic angular contact bearings -Electric fan cooled |

Tools Accessories:

| - Standard Tool box and accessories (4 Nos tool bits, Alen Key set, & Er-32 Wrench) |

Weihong NK105 G3 Milling Control System (Taiwan):

| -Handheld Membrane Type - 2/3D controller - Real time Computing - Closed loop servo control - Job loading through Network and execution. - Minimum and maximum depth control. - Online job resizing and mirroring. - Online Trouble shooting. - Automatic software upgrading. - 4 Axis and 3D laser scanner compatible. - Contour scanning compatible |

Motors and Drives (Yaskawa-Japan):

| - Yaskawa 750W Servo Motors - Heavy duty motors with peak torque of 45Nm • Real-time auto tuning enables machines to achieve a high dynamic performance • High-quality motor bearings • Integrated Safe Torque Off (STO) • Integrated internal positioning function • Integrated braking resistor in all frame sizes |

Inverter from Delta (Japan)-2nos:

| Nominal Input VAC: 480 Volts AC Input Range VAC: 380 to 480 Volts AC HP (CT): 15 Horsepower Amps (CT): 24 Amps Input Phase: 3 Operator Controls: Keypad Included Max. Frequency: 400 Hertz Braking Type: DC Injection; Dynamic Braking Pneumatic weight compensators - Compressed air is required (7 bar) |

Table Top:

| - Hybrid Aluminum T-Slot Vacuum Table - Vacuum as well as mechanical clamping is possible. - Dry running high pressure vacuum pump 3.3/4.4 KW 3-phase - 140 m3/h / 82 cfm (50 Hz) or 175 m3/h / 103 cfm (60 Hz) - ultimate vacuum of 28.2"Hg (60 mbar abs.) - Includes dust filter, on/off switch, overload |

Tool Box and accessories:

| - Allen Set Metric - ER 32 Wrenches - Tool changer block - Rubber Gasket 40M - Ambiglon grease 1 cartridges for vacuum pump |

Training and Installation:

| Machine Errection and Installation 1 Day Machine maintenance 1 Day Machine Operation 2 days |

AUTO COPYING & SHAPING MACHINE

MADE IN TAIWAN

SPECIFICATIONS:

| WORKING CAPACITY | 30-210*165-1000MM (Φ*L) |

| MAIN SPINDLE POWER | 7.5HP*2 |

| REVOLUTION SPEED | 5800-6000RPM |

| HYDRAULIC POWER | 2HP*1 |

| POWER OF BRAKING MOTOR | 2HP*1 |

| MACHINE SIZE | 3600*1050*2100MM |

| MEASUREMENTS | 3700*1150*2250MM |

| N.W. / G.W | 2400/2700KGS |

HYDRAULIC COPYING LATHE

MADE IN TAIWAN

SPECIFICATIONS:

| WORKING LENGTH | 100 - 1500MM |

| WORKING DIA | 20 - 120MM |

| MAIN SPINDLE POWER | 7.5HP & 3HP |

| FREQUENCY CONVERSION | 7.5 HP |

| MEASUREMENTS | 345X135X195 CM |

| N.W. / G.W | 1600 / 1800 Kgs |

CNC SIX SPINDLES MORTISER(Two -process)

MADE IN TAIWAN

SPECIFICATIONS:

| CYLINDER CLAMPING UNIT WITH SLIDE TABLE | 6 SETS |

| SPINDLE PITCH | 255MM |

| MAX. WORKPIECE LENGTH / WIDTH / THICKNESS | 1500 / 25-140 / 120 MM |

| X-AXIS TRAVEL | 1500 MM |

| Y-AXIS TRAVEL | 1530 MM |

| Z-AXIS TRAVEL | 200 MM |

| DISTANCE BETWEEN SPINDLE | 255 MM(3 SPINDLES) |

| SPINDLE SPEED | MAX. 18000 RPM |

| SPINDLE MOTOR: | 3.5KW X6 |

| SERVO MOTOR | 2KW*2& 1KW*1 |

| LUBRICATION | AUTOMATIC |

| MACHINE DIMENSIONS | 2200X2600X1900 MM |

| MACHINE WEIGHT | 1430KG |

PENUMATIC HINGE INSTALLATION MACHINE

MADE IN TAIWAN

SPECIFICATIONS:

| MOTOR | 1HP 415V 3PH |

| NW | 95KGS GW:125KGS |

| HINGE BORING HEAD (3-SPINDLE BORING HEAD) | 1UNIT |

| TUNGSTEN CARBIDE STEEL TIPPED DRILL Ø35MM | 1UNIT |

| TUNGSTEN CARBIDE STEEL TIPPED DRILL Ø10MM | 2UNITS |

DUST COLLECTION SYSTEM

MADE IN TAIWAN

A-GRADE:

| Using negative pressure putting all the dust straight to the Cyclone which controls almost 70% of the sucked dust, rest 30% of the dust will come in contact with the Hopper then air passes through the blower. In this way electricity consumption is equal to the System B-DRAE., but chances of damaging to the blower is almost nil. As saw & chips of wood will come in contact with the Cyclone first then to the Hopper and also choking possibilities are almost nil. This system also occupies lesser space in your factory premises, but the performance is much better than traditional bag systems. (For specifications kindly check: System 2+SHIELD.) |

B-GRADE:

| Using negative pressure putting all the dust straight to the Cyclone which controls almost 70% of the sucked dust, rest 30% of the dust will come in contact with the Hopper then air passes through the blower. In this way electricity consumption is little higher than System 1&2., but chances of damaging to the blower is lower than System.1 & 2 as saw & chips of wood will come in contact with the Cyclone first then to the Hopper and also choking possibilities are lower than System.1 & 2. (For specifications kindly check: System 1+SHIELD.) |

C-GRADE:

| Using negative pressure putting all the dust straight to the Hopper then air passes through the blower. In this way electricity consumption is little higher than System 1., but chances of damaging to the blower is lower as saw & chips of wood will come in contact with the Hopper directly and also choking possibilities are low. (For specifications kindly check: System 1.) |

D-GRADE:

| Using positive pressure putting all the dust straight to the blower then to the hopper. This way electricity can be reduced, but chances of damaging to the blower is high as saw & chips of wood will come in contact with the blower directly and also it can choke the system in short time. (For specifications kindly check: System 1.) |

FINGER JOINTER

MADE IN TAIWAN

SPECIFICATIONS:

SHAPER:

| Max. working table width | 450 mm |

| Range of workpiece width | 150 - 1000 mm |

| Range of workpiece height | 20 - 160 mm |

| Table moving speed Air/Oil cylinder variable speed | 0 - 20 m/min |

| Trim saw motor | 5 HP |

| Shaper cutter motor | 15 HP |

| Material of Cutter | Tungsten Carbide |

| Dia. of Cutter (in/out) | ø70 / ø160 mm |

| Main Sawblade | 3t x ø74 x ø255 (80T) |

| Auxiliaryliary Sawblade | 12t x ø74 x ø240 (20T) |

| Dust hood outlet diameter | 6" x 1, 4" x 1 |

| Machine dimensions (LxWxH) | 1830 x 840 x 1300 mm |

| Net weight | 770 Kgs |

| Noise level | 88.2 Db |

| Packing dimensions (LxHxW) | 1930 x 940 x1250 mm |

| Gross weight | 850 Kgs |

| Gluing | - |

FEEDING TABLE:

| Table width | 450 mm |

| Roller sizes | ø57 x 450 mm |

| Machine height | 970 mm |

| Machine length | 1000 mm |

| Machine width | 655 mm |

| Packing dimensions (F-D05P1 + F-D05P2) | 1000 x 19805 x 880 mm |

ASSEMBLER:

| Available length of product | 4500 mm |

| Available thickness of product | 20 - 60 mm |

| Available width of product | 20 - 160 mm |

| Feeding speed | 80 m/min |

| Product length capacity | 4 ~ 6 pcs |

| Max. : assembly pressure | 0 ~ 150 Kg/cm² |

| Feed drive motor | 1 HP , 2 HP |

| Hydraulic power unit | 5 HP |

| Cut-off saw | 5 HP |

| Dust hood outlet diameter | 4" (101.6mm) |

| Machine dimensions (LxHxW) | 7990 x 965 x 1350 mm |

| Noise level | 84 Db |

| Packing dimensions (LxHxW) | 6360 x 1065 x 1450 mm |

VACUUM MEMBRANE PRESS

MADE IN TAIWAN

SPECIFICATIONS:

| WORK TABLE SIZE | 10X5 FEET |

| MAX. THICKNESS | 50 MM |

| AVERAGE CYCLE TIME | 3-5 M\MIN |

| VACUUM | -0.1 MPA |

| HEATING SYSTEM | THROUGH HEATERS |

| PVC FOIL THICKNESS | 0.30-0.40 MM |

| TOTAL POWER | 18 KW |

| WORKING TABLES | 1 |

DOUBLE END TENNONER

MADE IN TAIWAN

SPECIFICATIONS:

| Max. working width | 2450mm |

| Min. working width | 210mm |

| Max. working thickness | 60mm |

| Motor horse power | 2hp |

| Feed speed | 5-25m/min |

| Distance between dogs | 400(300/200)mm |

| Motor horse power | 1hp |

| Feed speed | 2m/min |

| Motor horse power | 2(3/5)hp |

| Spindle speed | 3450rpm(60Hz) |

| Spindle diameter | 25.4(30)mm |

| Sawblade diameter | 205mm |

| Motor horse power | 5(7.5)hp |

| Spindle speed | 3450rpm(60Hz) |

| Spindle diameter | 25.4(30)mm |

| Sawblade diameter | 255mm |

Moulding system:

| Motor horse power | 5(7.5/10)hp |

| Spindle speed | 3000/8000rpm |

| Spindle diameter | 40mm |

| Cutter diameter | 180-210mm |

| N.W. | 3150kg |

| G.W. | 3450kg |

| Machine size (mm) | 4240x2820x1470mm |

| Packing size (mm) | 4400x2280x1750mm |

DRYER & DEHUMIDIFIER

MADE IN TAIWAN

SPECIFICATIONS:

| MACHINE DIMENSION | 1990MM*1650MM*1722MM |

| 15 HP SCROLL COMPRESSOR FROM COPELAND (USA MADE) | 1 |

| 1/2 HP MAIN BLOWER AIR FLOW 60M /MIN WIND SPEED :4P. / SIZE:45CM*45CM | 3 |

| HEART SYSTEM :12 KW | 1 |

| INTERIOR EXHAUST BLOWER AIR FLOW 65M3 /MIN WIND SPEED :4P. / SIZE:65CM*65CM | 5 |

| CONTROL SYSTEM (1) TEMPERATURE CONTROL: HEART SYSTEM (2) HUMIDITY CONTROL: COMPRESSOR (3) ALL CONTROL ACCESSORIES BREAKER SWITCHGEAR & SYSTEM IS USE SHIH-LIN ELECTRIC (MADE IN TAIWAN). | 1 |

| (1)SINGLE PROCESS FORMING DESIGN, CONNECT TO MAIN POWER TO OPERATING THE MACHINE. (2)THE UNIT IS FAST INSTALLED AND CONVENIENT TO RELOCATE. (3)AUTOMATIC PROCESS TEMPERATURE AND MOISTURE CONTROL SYSTEM TO ENSURE QUALITY. (4)MAIN VOLTAGE ELECTRIC CURRENT COULD INDICATE THE LACKING WIRE PROTECTION SYSTEM. (5)MAINVOLTAGE/CURRENT DESIGNATE/LOADING PROTECTION /TEMPERATURE EXCEED DESIGNATE AND CIRCUIT PROTECTION CONTROL. (6)DRYING TIME :15 (LITER/HR). (7) DRY CAPACITY:1000CFT RECOMMENDS KILN DIMENSION :L:600CM*W500CM*H360CM | |

AUTO POWER FEEDER

MADE IN TAIWAN

SPECIFICATIONS:

| FEED SPEED | 4 SPEEDS |

| ROLLERS | 4 ROLLERS |

| ROLLER DIA | 100 mm |

| MOTOR | 1 HP |

| WEIGHT | 75 Kgs |

HEAVY DUTY MULTI RIP SAW

MADE IN TAIWAN

SPECIFICATIONS:

| Maximum working thickness X sawblade | 95x305(12") / 120x360(14") |

| Min. length of cut | 180 mm |

| max. cutting width | 300 mm |

| Mix. Width Work piece | 700 mm |

| Spindle speed | 3200rpm |

| Chain width | 300 mm |

| Spindle power | 30/40/50/60/75 HP(check above quotation) |

| Measurement | 1830x1560x1610 / 1850x1580x 1600 |

| Spindle speed | 3200rpm |

| Feeding speed | 6.7~35 M/min |

| Feeding power | 2 HP |

| N.W./G.W | 1600 /2000 2200 kgs |

HORIZONTAL DOUBLE HEAD BORING MACHINE

MADE IN TAIWAN

SPECIFICATIONS:

| MOTOR (WITH 1/2" CHUCK) | 2HP*2PCS |

| 300 MM UP/DOWN | |

| 300MM RIGHT LEFT | |

| 250MM STROKE IN ONE GO | |

| BORING HEAD TILT UP TO 45 DEGREE | |

| HOLD DOWN CLAMP*2PCS | |

EMBOSSING MACHINE

MADE IN TAIWAN

SPECIFICATIONS:

| TOTAL POWER | 21KW |

| WORKING WIDTH | 1300 |

| WORKING HEIGHT | 3-100MM |

| MAIN MOTOR | 3.7KW |

| LIFTING MOTOR | 1.1KW |

| HEATING TUBE (UPPER ROLLER) | 1.5KW X 9 (PCS) |

| OVERALL | 1600X2330X1620MM |

| WEIGHT | 1800KG |

PROFILE WRAPPING MACHINE

MADE IN TAIWAN

SPECIFICATIONS:

| WRAPPING WIDTH | 350 MM |

| THICKNESS | 2-90 MM |

| MIN. LENGTH OF PROFILE | 600 MM |

| WORKING SPEED | 5-60M/MIN |

| MAIN TRASMISSION POWER | 2.2 KW |

| POWER OF MELT TANK | 7.4 KW |

| CONTROL TYPE | PLC CONTROL SCREE |

| HEATION LAMP | 9 KW |

| SLOT NOZZLE HEATING POWER | 5 KW |

| WEIGHT | 2500 Kgs |

| USING WITH PUR HOT MELT GLUE CAN DO DIFFERENT KIND OF MATERIAL, LIKE PVC, VENEER, PAPER, CPL ECT AND BASE PROFILE FOR MDF, WPC, PVC PLASTIC, ALUMINUM. WHICH SUITABLE FOR VARIOUS FEILD OF PROFILE SUCH AS DOOR, WINDOWS,PICTURE FRAME, FLOORING etc. | |

12” JOINTER

MADE IN TAIWAN

SPECIFICATIONS:

| Table area | 305x 2020mm |

| Spindle speed | 5300 rpm |

| Spindle diameter | 100 mm |

| Cutterhead motor | 3HP Straight |

| cutterhead Knife sizes | 305 x 30 x 3 mm/ 3 pcs |

| Fence size | 150 x 1100 mm |

| Fence tilting | 90°~ 45° |

MANUAL BRUSH SANDER

MADE IN TAIWAN

SPECIFICATIONS:

| 2 SANDING HEADS MOTOR | 1.5HP |

| SANDING SPEED CONTROL BY VFD. 2 SANDING HEADS RUN THE SAME DIRECTION SINGLE SIDE MAX WORKING LENGTH | 300 MM |

| INCLUDING 15PCS OF SINGLE SANDING STRIP + WOOD BRUSH ON EACH HEAD, TOTAL 30PCS FOR 2 HEADS | |

| SPARE BRUSH SANDING STRIP + WOODEN BRUSH STIP STIP FOR SL-300B2 | |

| LENGTH | 300MM USD$5.2 X 15 PCS X 2 |

| HEADS | GRIT SIZE OF SANDING BRUSH CAN CHOOSE #80,#100,#120,#150,#180,#220,#240,#320, #400 GRIT |

COPY SHAPER

MADE IN TAIWAN

SPECIFICATIONS:

| RANGE OF CUTTING DIAMETER | 24" – 100” |

| MAXIMUM RECTANGULAR CUTTING (2:1) | 86" X 44" |

| TABLE DIAMETER | 72" |

| TABLE ROTATION SPEED (INFINITELY VARIABLE) | 0.4 - 4RPM |

| SPINDLE SPEED | 9000RPM |

| SPINDLE DIAMETER | 1",30MM,11/4" |

| CUTTER SIZE | 100MM |

| FOLLOWER ROLLER DIAMETER | 100MM |

| TABLE DRIVE MOTOR | 3 HP X 1 |

| SPINDLE DRIVE MOTOR | 10 HP X 2 |

| SANDING HEAD MOTOR | 3 HP X 1 |

| WEIGHT | 4450 / 4650 KGS |

HIGH SPEED TOOTHPICK SHARPENING MACHINE

MADE IN TAIWAN

SPECIFICATIONS:

| CYM-008H | CYM-008HF | |

| Productivity | 1050~1350PCS/MIN. | 1050~1350PCS/MIN. |

| Horsepower | 1HP + 4x1/2HP | 1HP + 3x1/2 HP |

| Net weight | 300 KGS | 300 KGS |

| Gross weight | 390 KGS | 390 KGS |

| Machine size ( L x W x H ) | 67" x 24" x 44" | 67" x 24" x 44" |

| Packing size ( L x W x H ) | 74" x 32" x 55" | 74" x 32" x 55" |

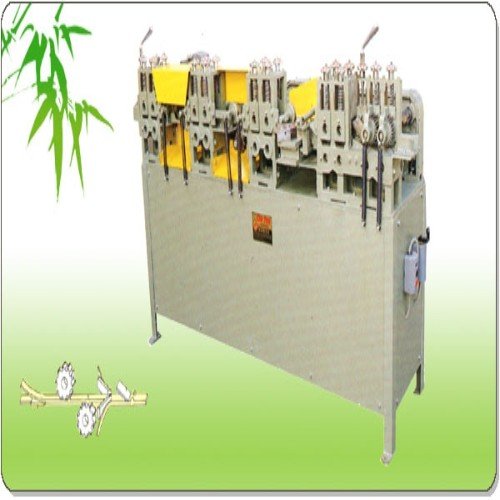

BAMBOO SLICING & KNOT REMOVING, WIDTH SIZING & PLANNING MACHINE

MADE IN TAIWAN

SPECIFICATIONS:

| Horsepower | 2HPx2 + 1HPx2 |

| Net weight | 530 KGS |

| Gross weight | 650 KGS |

| Machine size ( L x W x H ) | 74" x 22" x 41" |

| Packing size ( L x W x H ) | 78" x 25" x 51" |

BAMBOO MAT WEAVING MACHINE

MADE IN TAIWAN

SPECIFICATIONS:

| Specification | 6' |

| Productivity | 4-4.5 SQFT/MIN. |

| Horsepower | 1HP + 1/4 HP |

| Net weight | 1500 KGS |

| Gross weight | 1700 KGS |

| Machine size ( L x W x H ) | 94" x 99" x 69" |

| Packing size ( L x W x H ) | 87" x 104" x 79" |

BAMBOO STICK MAKING MACHINE

MADE IN TAIWAN

SPECIFICATIONS:

| Horsepower | 3HP + 3HP |

| Net weight | 330 KGS |

| Gross weight | 400 KGS |

| Machine size ( L x W x H ) | 52" x 28" x 35" |

| Packing size ( L x W x H ) | 58" x 35" x 48" |

AUTOMATIC BAMBOO RIP SAW

MADE IN TAIWAN

SPECIFICATIONS:

| Horsepower | 2 HPx1 + ⅛ HPx2 |

| Net weight | 480 kgs |

| Gross weight | 600 kgs |

| Machine size ( L x W x H ) | 125" x 31" x 75" |

| Packing size ( L x W x H ) | 129" x 35" x 73" |

BAMBOO OUTSIDE KNOT

MADE IN TAIWAN

SPECIFICATIONS:

| Horsepower | 1 HP x 1 |

| Net weight | 500 kgs |

| Gross weight | 650 kgs |

| Machine size ( L x W x H ) | 112" x 30" x 67" |

| Packing size ( L x W x H ) | 116" x 34" x 55" |

BAMBOO RIP SAW

MADE IN TAIWAN

SPECIFICATIONS:

| Horsepower | 5 HP x 2 |

| Net weight | 350 kgs |

| Gross weight | 450 kgs |

| Machine size ( L x W x H ) | 58" x 84" x 38" |

| Packing size ( L x W x H ) | 62" x 34" x 46" |

ROUND BAMBOO CROSS CUTTING MACHINE

MADE IN TAIWAN

SPECIFICATIONS:

| Horsepower | 2 HP x 1 |

| Net weight | 100 kgs |

| Gross weight | 160 kgs |

| Machine size ( L x W x H ) | 157" x 68" x 58" |

| Packing size ( L x W x H ) | 39" x 24" x 58" |

BAMBOO STRIP PLANNING MACHINE

MADE IN TAIWAN

SPECIFICATIONS:

| Horsepower | 3 HP x 4, 2 HP x 2 |

| Net weight | 900 kgs |

| Gross weight | 1050 kgs |

| Machine size ( L x W x H ) | 119" x 27" x 53" |

| Packing size ( L x W x H ) | 123" x 31" x 61" |

CARBONIZING BOILER

MADE IN TAIWAN

SPECIFICATIONS:

| Capacity | 2600 ~ 2700 pcs (1000mm) |

| Net weight | 1100 kgs |

| Gross weight | 1300 kgs |

| Machine size ( L x W x H ) | 240" x 60" x 66" |

| Packing size ( L x W x H ) | 112" x 61" x 67" |

DRYER

MADE IN TAIWAN

SPECIFICATIONS:

| Construction size | 15 M3 |

| Horsepower | 3 HP x 1 |

| Net weight | 1000 kgs |

| Gross weight | 1150 kgs |

| Machine size ( L x W x H ) | 77" x 39" x 86" |

| Packing size ( L x W x H ) | 83" x 43" x 90" |

4-SIDE PLANNING MACHINERY

MADE IN TAIWAN

SPECIFICATIONS:

| Horsepower | 5 HPx1, 2 HPx3, 1 HPx1 |

| Net weight | 650 kgs |

| Gross weight | 800 kgs |

| Machine size ( L x W x H ) | 66" x 41" x 45" |

| Packing size ( L x W x H ) | 69" x 44" x 51" |

STICK SIZING MACHINE

MADE IN TAIWAN

SPECIFICATIONS:

| Horsepower | 2 HP x 1 |

| Net weight | 90 kgs |

| Gross weight | 180 kgs |

| Machine size ( L x W x H ) | 74"x 24"x 35" |

| Packing size ( L x W x H ) | 78" x 28" x 39" |

GLUE APPLICATOR

MADE IN TAIWAN

SPECIFICATIONS:

| Horsepower | 3 HPx1 + 1 HPx1 + ½ HPx1 |

| Net weight | 700 kgs |

| Gross weight | 850 kgs |

| Machine size ( L x W x H ) | 65" x 64" x 52" |

| Packing size ( L x W x H ) | 68" x 35" x 63" |

HYDRAULIC HOT PRESS

MADE IN TAIWAN

SPECIFICATIONS:

| Main Machine | Vice Machine | |

| Working table ( L x W ) | 2550 x 1300 mm | |

| Capacity | 12 sq.m/hour (one cycle: 12-15 minutes) | |

| Top Pressure | 180 Tons | |

| Side Pressure | 80 Tons | |

| Horsepower | 15 HP x 1 | |

| Net weight | 11000 kgs | 1150 kgs |

| Gross weight | 11200 kgs | 1250 kgs |

| Machine size ( L x W x H ) | 108" x 93" x 81" | 51" x 40" x 55" |

| Packing size ( L x W x H ) | 112" x 97" x 87" | 55" x 44" x 61" |

ST. LINE RIP SAW FOR BAMBOO

MADE IN TAIWAN

SPECIFICATIONS:

| Minimum working length | 200 mm (8") |

| Maximum thickness | 82 mm (3.35") |

| Saw arbor speed | 4500 rpm |

| Saw blade diameter | 200 - 300 mm (8"-12") |

| Saw arbor diameter | 25.4 mm (1") |

| Feed speed | 15 / 20 / 25 m/min |

| Throat depth | 350 mm |

| Horsepower | 7½ HPx1 + ½ HPx1 |

| Net weight | 850 kgs |

| Gross weight | 1050 kgs |

| Machine size ( L x W x H ) | 60" x 38" x 53" |

| Packing size ( L x W x H ) | 59" x 45" x 58" |

BAMBOO PLANNING & MOULDING MACHINE

MADE IN TAIWAN

SPECIFICATIONS:

| Working range(mm) |

|

||||||

| Cutting spindle diameter | o 40 mm | ||||||

| Rev. speed of cutting spindle | 7200 rpm | ||||||

| Horsepower | 7½ HPx5 + 5 HPx1 + 1 HPx1 | ||||||

| Feed speeds(variable speed) | 6-24 m/min | ||||||

| Net weight | 3200 kgs | ||||||

| Gross weight | 3800 kgs | ||||||

| Machine size ( L x W x H ) | 141" x 58" x 60" | ||||||

| Packing size ( L x W x H ) | 146" x 66" x 67" |

BAMBOO SPLITTING MACHINE

MADE IN TAIWAN

SPECIFICATIONS:

| Specification | 6’ | 8’ | 10’ | 12’ |

| Spindle speed | 10 R.P.M | 9 R.P.M | 8 R.P.M | 7 R.P.M |

| Horsepower | 7½ HP x 1 | 7½ HP x 1 | 7½ HP x 1 | 7½ HP x 1 |

| Net weight | 530 kgs | 550 kgs | 570 kgs | 590 kgs |

| Gross weight | 590 kgs | 620 kgs | 650 kgs | 680 kgs |

| Machine size ( L x W x H ) | 150" x 35" x 50" | 174" x 35" x 50" | 198" x 35" x 50" | 222" x 35" x 50" |

| Packing size ( L x W x H ) | 156" x 44" x 58" | 180" x 44" x 58" | 204" x 44" x 58" | 228" x 44" x 58" |

AUTOMATIC EDGE BANDER MACHINE

MADE IN TAIWAN

SPECIFICATIONS:

| PREMILLED UNIT 48MM CUTTERHEAD (TRIM 45MM) | |

| PREHEATING UNIT | |

| END TRIMMING UNIT | |

| FLUSH AND RADIUS TRIMMING UNIT | |

| CORNER ROUNDING UNIT | |

| RADIUS SCRAP UNIT | |

| BUFFING UNIT |

AUTOMATIC TWIN-TABLE ROUND-END TENONER

MADE IN TAIWAN

SPECIFICATIONS:

| SPINDLE MOTOR: | 5HP 3PH |

| TCT THROW-AWAY TYPE HELICAL CUTTER HEAD | |

| PACKING SIZES: | (L×W×H)1430×1300×600MM |

| NW: 760KG G.W.: | 850KGS |

AUTOMATIC TWIN-TABLE SLOT MORTISER

MADE IN TAIWAN

SPECIFICATIONS:

| (OSCILLATION MORTISER) | |

| MORTISE OSCILLATION LENGTH | MAX. 120MM |

| MORTISE SLOT THICKNESS: | MAX. 30MM |

| MORTISE SLOT DEPTH: | MAX. 80MM |

| SPINDLE MOTOR: | 3HP |

| CUTTER OSCILLATION MOTOR: | 1/2HP |

| PACKING SIZE: | 90×140×135CM |

| N.W.:450KGS G.W.: | 530KGS |

BRUSH SANDER

MADE IN TAIWAN

SPECIFICATIONS:

| Maximum processing width (mm): | 1000 | 1300 | 1000 | 1300 |

| Maximum processing thickness (mm): | 100 | 100 | 100 | 100 |

| The shortest length of the workpiece (mm): | 450 | 450 | 450 | 450 |

| Straight brush horsepower: | 1HP | 2 HP | ||

| Disc brush horsepower: | 1 HP | 2 HP | ||

| Horizontal sand horsepower: | 1HP | 2HP | ||

| Conveyor belt horsepower: | 1HP | 2HP | 1HP | 2HP |

| Conveyor speed | 5 ~ 20M / minimum | 5 ~ 20M / minimum | ||

| Swing motor: | 1/8 HP | 1/4 HP | 1 / 8-20 | 1 / 4HP |

CNC BEAM SAW

MADE IN TAIWAN

SPECIFICATIONS:

| Max. cutting length | 3200mm | 3800mm |

| Max. cutting height | 100mm (Max.120mm) | |

| Main sawblade diameter | Ø405mm (Max. Ø455mm) | |

| Main sawblade arbor diameter | Ø60mm | |

| Scoring sawblade diameter | Ø180mm | |

| Scoring sawblade arbor diameter | Ø45mm | |

| Saw carriage forward speed | 5~100 M/min | |

| Saw carriage return speed | 120 M/min | |

| Main sawblade motor | 20HP (25HP optional) | |

| Scoring sawblade motor | 3HP | |

| Saw carriage drive motor | 1KW | |

| High pressure blower motor | 5HP | |

| Main pusher feed motor | 1KW | |

| Vice pusher feed motor | 1KW | |

| Machine bed blower motor | 3HP (optional) | |

| Number of grippers(Main+Vice) | 8+1 | 9+1 |

| Floating tables | 1800 x 600mm x 3unit | |

| Pusher feed speed | 5~80M/min | |

| Working air pressure | 6~7kg/cm2 | |

| Table height from floor | 920mm |

CNC DOVETAIL

MADE IN TAIWAN

SPECIFICATIONS:

| MACHINE SIZE (LXWLH): | 1500X840X1300MM |

| SPINDLE MOTOR: | 2 HP |

| SPINDLE SPEED: | 20, 000 RPM |

| MAX. WORKING WIDTH: | 600 MM |

| MAX. PANEL THICKNESS: | 25 MM |

| MIN. PANEL THICKNESS: | 8 MM |

| WORKING TABLE HEIGHT: | 850 MM |

| AIR PRESSURE: | 6KG |

| TENON SPACING (ADJUSTABLE): | 25 MM |

| POWER: | 5 HP |

| N.W/G.W | 700/ 720 KGS |

| Equipped with high frequency spindle motor (Up to 20,000RPM) | |

| The 2-axis servo motor controller offers greater productivity with high machining precision | |

| The linear guide ways and ball screws ensure excellent positioning accuracy | |

| User-friendly interface with 7-inch touch screen for controlling all data, including cutter bit diameter, working speed, panel width an dothers. | |

| Featured with cutter compensation for better cutter usage and perfect machining results. | |

| Example: when cutter dia. is resharpened from 13.5 mm to 13.2 mm, the cutter compensation function allows the machine to keep making the same size of tenons(13.5 mm) | |

| The rigid machine structure prevents vibrations, even during high speed machining. | |

| The machine provides a maximum working width of 600mm. | |

COPY SHAPER

MADE IN TAIWAN

SPECIFICATIONS:

| RANGE OF CUTTING DIAMETER: | 1” – 36” |

| MAXIMUM RECTANGULAR CUTTING (2:1): | 25" X 12.5" |

| TABLE DIAMETER: | 30" |

| TABLE ROTATION SPEED (INFINITELY VARIABLE): | 0.5 - 4RPM |

| SPINDLE SPEED: | 8000RPM |

| SPINDLE DIAMETER: | 1",30MM,11/4" |

| INTERCHANGEABLE: | ONE DIA FUNISHED |

| CUTTER SIZE: | 100MM |

| FOLLOWER ROLLER DIAMETER: | 100MM |

| TABLE DRIVE MOTOR: | 1 HP X 1 |

| SPINDLE DRIVE MOTOR: | 7.5 HP X 1 |

| WEIGHT: | 860 / 1060 KGS |

CUT OFF SAW

MADE IN TAIWAN

SPECIFICATIONS:

| CUTTING CAPACITY (THICKNESS X WIDTH: | 2" X 12", 3" X 11", 4" X 10" |

| CYCLE SPEED: | 45 CUTS/MIN |

| CYCLE OPERATION: | PNEUMATIC |

| SAW ARBOR DIAMETER: | Ø1"/ 30MM |

| SAW BLADE SPEED: | 3600 RPM |

| DUST EXHAUST DIAMETER: | Ø4" X (1) |

| SAW ARBOR MOTOR: | 7.5HP |

| TABLE SIZE: | 660X 690MM |

| NET WEIGHT: | 350 KGS |

| GROSS WEIGHT: | 410 KGS |

| PACKING DIMENSIONS(LXWXH): | 940 X 850 X 1350 MM |

DOUBLE SURFACE PLANNERS

MADE IN TAIWAN

SPECIFICATIONS:

| MAXIMUM WORKING WIDTH: | 635MM |

| MAXIMUM WORKING THICKNESS: | 200MM |

| MINIMUM WORKING THICKNESS: | 10MM |

| MINIMUM WORKING LENGTH: | 310MM |

| HELICAL CUTTERHEAD INSERT: | 15*15*2.5MM KNIVES |

| TOP CUTTERHEAD MOTOR: | 20HP |

| BOTTOM CUTTERHEAD MOTOR: | 15HP |

| FEEDING MOTOR: | 3HP |

| ELEVATION MOTOR: | 1/2HP |

| VARIABLE FEED SPEED BY FREQUENCY INVERTER | |

| DIGITAL POSITION CONTROLLER | |

| COLUMN LIFT | |

DOVETAIL

MADE IN TAIWAN

SPECIFICATIONS:

| TENON THICKNESS: | MIN. 7 MM – MAX. 20 MM |

| TENON WIDTH: | MIN. 6 MM – MAX. 18 MM |

| TENON DEPTH: | MIN. 10 MM – MAX. 30 MM |

| SPINDLE VERTICAL ADJUSTMENT: | 30 MM |

| MAX. WORK PIECE SIZE: | L: 1500 MM, W: 480 MM |

| AIR CLAMP: | HORIZONTAL |

| COLLET CHUCK CAPACITY: | 12 MM |

| NO. OF AIR CLAMPS: | 4 PCS |

| SPINDLE SPEED: | 20,000 RPM |

| SPINDLE MOTOR: | 2 HP |

| FEEDING MOTOR: | 2 HP |

| WORKING AIR PRESSURE: | 5 KG |

| N.W / G.W: | 467 / 570 Kgs |

FOUR SPINDLES MOULDER (SAFETY GUARD)

MADE IN TAIWAN

SPECIFICATIONS:

| Bottom horizontal: | 7.5HP |

| Right、left vertical: | 10 HP |

| Top horizontal: | 7.5 HP |

| Feeding motor: | 3HP |

| Elevator motor: | 1/3 HP |

| Feeding speed: | 6-25 m/min |

| Planing width: | 10-230mm |

| Planing thickness: | 7-125mm |

| Spindle speed: | 6000RPM |

| Spindle diameter: | Φ40MM |

| Infeed table length: | 2000mm |

| Safety guard | |

| Table hard chrome plated: | 1set |

| Table lower roller transmission: | 1 set |

| Tool box: | 1 set |

| Planer knives: | 1 set |

| (Horizontal : D125*d40*8” 4T, vertical : D125*d40*3” 4T) | |

GLUE SPREADER

MADE IN TAIWAN

SPECIFICATIONS:

| WORKING WIDTH: | 400 MM |

| IN-FEED LENGTH: | 1890 MM |

| OUT-FEED LENGTH: | 2890 MM |

| GLUE ROLLER LENGTH: | 420 MM |

| DRIVE MOTOR: | 1HP 60:1 |

| MACHINE LENGTH: | 5 Mtr |

HIGH FREQUENCY GENERATOR

MADE IN TAIWAN

SPECIFICATIONS:

| INPUT POWER: | 3 Ø 415 V 30 KVA |

| OUTPUT POWER: | 20KW Two Side Out |

| TRANSMITTING TUBE: | PATENTED |

| R.F ADJUST: | Hand Wheel Adjuster |

| High Tension Transformer: | AC8000V, DC10000V. 50KVA |

| VARIABLE CAPACITOR: | Permanent Warranty |

| MACHINE DIMENSIONS: | L:1100 W: 1300 H: 1700 mm |

| MACHINE WEIGHT NW: | 650 KGS |

HIGH FREQUENCY PRESS

MADE IN TAIWAN

SPECIFICATIONS:

| Input Power: | 3 Ø 415V |

| Output Power: | 100 tons |

| Working Area: | Top Platen : 950 X 1600mm |

| Cylinders Top: | 150 X 4pcs x 400mm |

| Opening (Daylight): | One daylight, Opening 1200mm (from top to bottom) |

| Hydraulic Power: | 3HP |

| Pressing Way Top side pressure | |

| Plate Balancing 4 side equipped with gear shaft levelling device. | |

| Emergency Button Equipped with Emergency button at front side of machine. | |

| Emergency Pull Wire Front side with emergency pull wire. | |

| Grounding Whole press grounding. | |

| Control system Standard control system. | |

| Dimension: | L:2100 W:1070 H:2050mm |

| Weight: | NW:2400KGS. GW:2550KGS |

| Package Wooden Pallet | 1400 X 1300 mm |

High Frequency Press – Dual Table

MADE IN TAIWAN

SPECIFICATIONS:

| Input Power: | 3 Ø 415V |

| High Frequency Power: | 25 KW |

| Transmitting Tube: | 8T25RA CANON |

| H.F. Adjustor Hand wheel adjustor | |

| High Tension Transformer: | AC8000V, DC10000V. 40KVA |

| Rectifier Patented, High Tension resistance, Full wave | |

| Variable Capacitor Patented, 4 piece one Set, | |

| Press Work Range Max: | 1220 X 2440 X 15~50mm |

| Pressure Apply V: | 5HP Hydraulic system |

| Pressing Way Upper and Side pressure | |

| Cylinders: | UP× 4 PCS / Side x 4 PCS / Rear 8PCS |

| Inlet feeding Table Motor drive chained Pusher | |

| Anti-Glue-Stick Upper plate with Anti-Glue-Stick to prevent glue from stick on | |

| Protection: Tube Protector Patented tube protector is to protect the expensive tube from over-heat burnt | |

| Spark Suppressor Patented spark suppressor is to protect machine plate and work piece from short voltage burnt | |

| Grounding Whole plate grounding | |

| Control system Standard control system | |

| Dimension: | L:5600mm W:2200mm H: 2100mm |

| Weight: | NW:5600KGS. GW:5950KGS |

HIGH FREQUENCY PRESS FLAT BED

MADE IN TAIWAN

SPECIFICATIONS:

| INPUT POWER: | 3 Ø 415V |

| HIGH FREQUENCY POWER: | 30 KW |

| TRANSMITTING TUBE: | CANON |

| H.F. ADJUSTOR: | HAND WHEEL ADJUSTOR |

| HIGH TENSION TRANSFORMER: | DC 6 KV – 10 KV 50 KVA |

| INVERTER FEED SPEED: | 11-26 M/MIN |

| RECTIFIER: | PATENTED, HIGH TENSION RESISTANCE FULL WAVE |

| VARIABLE CAPACITOR: | PATENTED, 4 PIECE ONE SET, |

| WORKING AREA: | MAX RANGE : 2440 X 1220 X 15~55MM |

| PRESSURE: | V 5HP HYDRAULIC PUMP |

| PRESSING WAY: | UPPER & REAR PRESSURE |

| CYLINDER: | UP X 3 PCS / REAR X 12 PCS |

| LOADING AND UNLOADING: | MOTOR DRIVE CHAIN PUSHER |

| UP AND LOWER TEFLON SHEET & UPPER AND BOTTOM PLATE SURFACE ATTACHED WITH STEEL PLATES. | |

| TUBE PROTECTOR PATENTED TUBE PROTECTOR IS TO PROTECT THE EXPENSIVE TUBE FROM OVER-HEAT BURNT | |

| SPARK SUPPRESSOR PATENTED SPARK SUPPRESSOR IS TO PROTECT MACHINE PLATE AND WORK PIECE FROM SHORT VOLTAGE BURNT | |

| GROUNDING: | WHOLE PLATE GROUNDING |

| PLATE POSITIONINGL PROTECTION: | UPPER PLATE POSITIONING PRESSING PROTECTION |

| CONTROL SYSTEM: | STANDARD CONTROL SYSTEM |

| DIMENSION: | L:6500MM W:2200MM H:1900MM |

| WEIGHT NW: | 5200KGS. GW:6200KGS. |

HIGH FREQUENCY PRESS –SLANTED BED

MADE IN TAIWAN

SPECIFICATIONS:

| INPUT POWER: | 3 Ø 415V |

| HIGH FREQUENCY POWER: | 25 KW |

| TRANSMITTING TUBE: | CANON |

| H.F. ADJUSTOR: | HAND WHEEL ADJUSTOR |

| HIGH TENSION TRANSFORMER: | AC8000V, DC10000V. 40KVA |

| RECTIFIER: | PATENTED, HIGH TENSION RESISTANCE FULL WAVE |

| VARIABLE CAPACITOR: | PATENTED, 4 PIECE ONE SET, |

| WORKING AREA: | MAX RANGE : 2440 X 1220 X 15~55MM, SLANTED BED |

| PRESSURE: | V 5HP HYDRAULIC PUMP |

| PRESSING WAY: | V UP AND SIDE PRESSURE AS WELL AS UPPER MASSIVE PLATE |

| CYLINDER: | UP× 2 PCS / REAR X 10 PCS / SIDE X 2 PCS |

| LOADING AND UNLOADING: | MANUALLY LOADING AND UNLOADING |

| UP AND LOWER PLATE UPPER AND BOTTOM PLATE SURFACE ATTACHED WITH STEEL PLATES. | |

| PRESS TYPE DUAL INCLINED BED WITH ONE MASSIVE UPPER PLATE SLIDES LEFT AND RIGHT SIDE FOR UP SIDE PRESSING | |

| TUBE PROTECTOR PATENTED TUBE PROTECTOR IS TO PROTECT THE EXPENSIVE TUBE FROM OVER-HEAT BURNT | |

| SPARK SUPPRESSOR PATENTED SPARK SUPPRESSOR IS TO PROTECT MACHINE PLATE AND WORK PIECE FROM SHORT VOLTAGE BURNT | |

| GROUNDING: | WHOLE PLATE GROUNDING |

| PLATE POSITIONINGL PROTECTION: | UPPER PLATE POSITIONING PRESSING PROTECTION |

| CONTROL SYSTEM: | STANDARD CONTROL SYSTEM |

| DIMENSION: | L:6500MM W:2200MM H:1900MM |

| WEIGHT NW: | 5000KGS. GW:6000KGS |

MULTI BORING SINGLE HEAD

MADE IN TAIWAN

SPECIFICATIONS:

| Max. distance between center | 32mm | 32mm | 32mm |

| Number of spindle per boring head | 21 | 27 | 35 |

| Max. drilling depth | 75mm | 75mm | 75mm |

| Boring head adjustment | 0°~90° | 0°~90° | 0°~90° |

| Table size | 872 x 490mm | 1070 x 490mm | 1325 x 490mm |

| Spindle speed | 2800rpm | 2800rpm | 2800rpm |

| Motor | 2.5HP | 2.5HP | 2.5HP x 2 |

| N.W./G.W. | 350kgs/430kgs | 400kgs/480kgs/550kgs/650kgs | 550kgs/680kgs |

| Machine size | 968 x 820 x 1220mm | 1220 x 820 x 1370mm | 1470 x 820 x 1250mm |

| Packing size | 1143 x 889 x 1372mm | 1270 x 889 x 1372mm | 1550 x 889 x 1372mm |

MULTI BORING THREE HEAD

MADE IN TAIWAN

SPECIFICATIONS:

| Max. distance between centers | 32mm |

| Number of spindle per boring head | 21+21+21 |

| Max. boring depth | 80mm |

| Total motor power | 2HP x 3 |

| Spindle speed | 2800rpm |

| Max. distance vertical head | 1100mm |

| N.W./G.W. | 620kgs/730kgs |

| Machine size | 2000 x 1260 x 1300mm |

| Packing size | 2235 x 1320 x 1575mm (88" x 52" x 62") |

PANEL-SAW

MADE IN TAIWAN

SPECIFICATIONS:

| SLIDING TABLE: | 3200X378MM |

| MANUAL RISE/FALL & TILTING FOR MAIN SAW BLADE AND SCORING BLADE | |

| THREE SPEED: | 3000,4000,5000 |

| RIP FENCE, MANUAL WITH CUTTING WIDTH: | 1300MM |

| CROSSCUT-MITER FENCE, MANUAL FOR LENGTH AND ANGLE ADJUSTMENT | |

| CROSSCUT TO 3200MM | |

| WITHOUT MAIN SAW BLADE, WITH SCORING BLADE | |

| WITH DIGITAL READOUT FOR TILTING CUTTING | |

| WITH HOLD DOWN AND EDGE SHOE | |

PIN ROUTER

MADE IN TAIWAN

SPECIFICATIONS:

| HEAVY DUTY CAST IRON FRAME | |

| DISTANCE FROM SPINDLE TO COLUMN: | 750MM |

| SPINDLE TRAVEL: | 90 MM |

| VERTICAL ADJUSTMENT OF TABLE: | 185MM |

| DIMENSION OF WORKING TABLE: | 900 X 1000 MM |

| MOTOR: | 7.5 HP |

| SPINDLE SPEED: | 10000/20000RPM |

| TABLE CAN BE TILTED TO 35 DEGREE | |

| 3 ADJUSTABLE STOPS FOR CUTTING DEPTH | |

| SPINDLE UP AND DOWN PNEUMATICALLY CONTROLLED, | |

| WITH COLLETS AND GUIDE PINS | 6MM,8MM,9MM,12MM,16MM OR 1/4", 5/16", 3/8", 1/2", 5/8" (SHALL BE INFORMED WHILE FINALISING ORDER) |

PNEUMATIC & HYDRAULIC CLAMP CARRIER

MADE IN TAIWAN

SPECIFICATIONS:

| WORKING SIZE: | L=103” W=50” T=1”~ 3-2/1” |

| 06 SECTIONS × 08 CLAMPS: | TOTAL 48 PCS |

| CLAMP WORKING LENGTH: | 50” |

| CLAMP THICKNESS: | 1”~ 3-2/1” |

| MAX. WORKING WIDTH: | 103” |

| HYDRAULIC WRENCH: | *1PCS |

| HOLD DOWN BAR: | *1PCS |

| MOTOR: | 2HP 6P |

| SPEED REDUCERS: | 135# 1/600 |

| OIL TANK: | 2HP*20L |

| OIL PRESSURE | OMP100 |

SEMI AUTO BEAM SAW

MADE IN TAIWAN

SPECIFICATIONS:

| Model: | TPS-8 | TPS-10 | TPS-12 |

| Max. cutting length: | 2600mm | 3200mm | 3800mm |

| Max. cutting height | Max. 90mm | ||

| Main sawblade diameter | Ø355mm | ||

| Main sawblade arbor diameter | Ø25.4mm(Ø30mm optional) | ||

| Scoring sawblade diameter | Ø160mm | ||

| Scoring sawblade arbor diameter | Ø25.4mm(Ø30mm optional) | ||

| Saw carriage forward speed | 12~16~21~26 M/min | ||

| Saw carriage return speed | 24~32~42~52 M/min | ||

| Main sawblade motor | 13HP(15HP optional) | ||

| Saw carriage drive motor | 3HP | ||

| Infeed roller tables | 1200 x 200mm x 3unit | ||

| Outfeed flat tables | 1200 x 200mm x 3unit | ||

| Working air pressure | 5~6kg/cm2 | ||

| Table height from floor | 890mm | ||

SINGLE HEAD BAND RESAW

MADE IN TAIWAN

SPECIFICATIONS:

| WITH DIGITAL READOUT | |

| MAX. WORKING SIZE: | 610MM(W) X 250MM(H) |

| DISTANCE FROM BLADE TO CONVEYOR TABLE: | 4-250MM |

| CONVEYOR BELT SIZE: | 585MM(W) X 5470MM(L) |

| SAW WHEEL DIMENSION: | Φ28" X 2"(THICKNESS) |

| MAX FEED SPEED: | 15M/MIN |

| SAW WHEEL MOTOR: | 30HP |

| HYDRAULIC PRESSURE: | 55KGS/CM2 |

| DUST HOOD DIAMETER: | 4" X 2" |

| SAW BLADE SIZE: | 195.5"(L) X 2"(W) |

| HYDRAULIC SYSTEM | MOTOR 3HP / IN-FEED SPEED WP250 / OUT-FEED SPEED WP160 |

| ELEVATION MOTOR | 1/4HP 6P |

| PACKING DIMENSIONS WITH PALLET | 2880 X 2260 X 2160MM |

| MACHINE N.W.: | 2000 KG |

| PNEUMATIC PRESSURE ROLLER SYSTEM FOR ACCURATE CUTTING | |

| HOLD DOWN ROLLER BY AIR CYLINDER | |

| WITH RETURN CONVEYOR: | BELT SIZE 185MM X 5470MM |

| WITH MIST COOLANT SYSTEM FOR SAW BLADE | |

| WITH AIR/HYDRAULIC COMPENSATION SYSTEM FOR BLADE TENSIONING | |

| WITH 30HP INVERTER | |

| SAW KERF | 1.35MM |

STRAIGHT LINE RIP SAW

MADE IN TAIWAN

SPECIFICATIONS:

| TABLE SURFACE: | 2000X1160MM |

| PROCESSING WIDTH: | 660MM |

| CUTTING THICKNESS: | 132MM |

| SAWBLADE DIA: | 355-455MM |

| SAWBLADE BORE: | 50.8MM |

| INVERTER FEED SPEED: | 11-26 M/MIN |

| REVOLUTION OF ARBOR SAW: | 2850 R.P.M/50HZ |

| FEEDING MOTOR: | 2 HP |

| SPINDLE POWER: | 15 HP |

| MEASUREMENT: | 2270X1710X1550MM |

| GROSS WEIGHT: | 1700KGS/1900KGS |

TABLE SAW

MADE IN TAIWAN

SPECIFICATIONS:

| DIA SAW BLADE: | 12” |

| MAX. CUT AT 90 DEGREE: | 4” |

| MAX. CUT AT 45 DEGREE: | 70 MM |

| BORE DIA: | 1” OR 30 MM |

| ARBOR SPEED: | 4000 RPM |

| TABLE SIZE: | 1220 X 762 MM |

| TABLE HEIGHT: | 857 MM |

| SLIDING TABLE CAPACITY: | 1220 X 2440 MM |

| MAX. RIP TO RIGHT SIDE OF BLADE: | 1270 MM |

| MOTOR: | 5 HP |

| N.W / G.W: | 260 KGS / 320 KGS |

THICKNESS PLANNER

MADE IN TAIWAN

SPECIFICATIONS:

| TABLE AREA: | 635*775MM |

| MAX. PLANING WIDTH: | 610 MM |

| MAX. PLANING THICKNESS: | 178 MM |

| MIN. PLANING THICKNESS: | 3 MM |

| MAX. CUTTING DEPTH: | 6.4 MM |

| CUTTINGHEAD MOTOR: | 7.5HP |

| SPIRAL CUTTERHEAD: | 15X15X2.5 |

| CUTTERHEAD SPEED: | 5200 RPM |

| CUTTING DIAMETER: | 77 MM |

| FEED SPEED: | 8M/MIN |

TILTING SPINDLE MOULDER

MADE IN TAIWAN

SPECIFICATIONS:

| FORWARD TILT | |

| DIMENSION OF WORKING TABLE: | 800X1000MM |

| TABLE HEIGHT: | 900MM |

| TILTING SPINDLE: | -5- +45 DEGREE |

| MOTOR: | 7.5HP |

| 5 SPINDLE SPEEDS: | 3000/4000/6000/8000/10000RPM |

| INTERCHANGEABLE SPINDLE | |

| SPINDLE ROTATION: | FORWARD AND REVERSE |

| MAX. TOOL DIAMETER: | BELOW TABLE 210MM, ABOVE TABLE 335MM |

| COLLET CHUCK ACCEPTABLE | |

| WITH FULLY ADJUSTABLE FENCE ASSEMBLY FOR STRAIGHT WORK | |

| MITRE GAUGE, EXTENSION BAR, | |

| HOLD DOWN DEVICE | |

VERTICAL BAND SAW

MADE IN TAIWAN

SPECIFICATIONS:

| MODEL: | 5300 | 6300 |

| Motor: | 3HP/5HP 1 & 3 phase(2.25kw) | 5 HP, 1 phase & 3 phase(3.75kw,2.25kw) |

| Table Size(LXWXH): | 29.6"x20.8"x2" (750 x 530 x 50 mm) | 33 1/2" x 23 5/8" x 2" (850 x 600 x 50mm) |

| Cast Iron Wheel Size: | 21" (530 mm) | 25" (630 mm) |

| Cutting Height: | 14"(350 mm) | 16" (400mm) |

| Max. Cutting Width (w/o fence): | 20" (510 mm) | 24-1/2" (622 mm) |

| Max. Cutting Width (with fence): | 18-1/4"(465 mm) | 22 1/2" (570 mm) |

| Saw Blade Length: | 165" (4190 mm) | 181" (4600 mm) |

| Saw Blade Width: | 1/4 ~ 1-3/8" (6 mm - 35 mm) Standard 1" (Standard 25 mm) | 1/4"-1 1/2" (6 mm-38 mm) Standard 1" (Standard 25 mm) |

| Saw Blade Speed: | 1370 M/min (4500 FPM) Single Speed (820 rpm) | 1615 M/min (5300 FPM) Single Speed (820 rpm) |

| Table Tilting: | 45° /20° (CE) | 45°(R)/ 20°(CE) |

| Table Height: | 35 -1/2" (900 mm) | 33" (830 mm) |

| Dust Chute: | 4" x 2 pcs (100mm x 2 pcs) | 4" x 2 pcs (100mm x 2 pcs) |

| Braking System: | Foot pedal+Micro switch (Electronic Braking Switch System) | Foot Pedal+Micro Switch (Electronic Braking Switch System) |

| BladeE Guide: | Ball bearing (European roller disc type) | Ball Bearing (European roller disc type) |

| Driving Belt: | A type x 2 Grooves | A Type x 2 Grooves |

| Cast Iron Fence: | 1-1/4"(W) x 3-5/8"(H) (30(W) x 90(H) mm) | 1-1/4"(W) x 3-5/8"(H) (30(W) x 90(H) mm) |

| Sound Rating: | 63-70 db | 63-70 db |

| Base Size (LXWXH): | 33-1/2"x 21-5/8"x 3-1/8" (850 x 550 x 80 mm) | 41 3/8"x 23 5/8"x 3 1/4" (1,050 x 600 x 80 mm) |

| Machine Size (LXWXH) | 39.4"x 28.3"x 78 " (1002 x 727 x 1982 mm) | 47"x 29 1/2"x 81" (1,190 x 750 x 2,060 mm) |

| Packing Size: | 39.4"x 29.1"x 94.8" (1006 x 740 x 2410 mm) | 45 1/4"x 29 1/2"x 87" (1,150 x 750 x 2,210 mm) |

| N.W/G.W.: | 580 / 678 lbs (264 / 308 kgs) | 836 / 957 lbs (380 / 435 kgs) |

| Ctn Qty 20'/40': | 17 / 35 sets (17 / 35 sets) | 14 sets / 30 sets |

WIDE BELT SANDER

MADE IN TAIWAN

SPECIFICATIONS:

| MAX. WORKING WIDTH: | 1300 MM |

| MAX. WORKING THICKNESS: | 3-130 MM |

| N SPIRAL CUTTING HEAD DIA: | ∮160 MOTOR: 25HP |

| R. RUBBER WHEEL DIAMETER: | ∮220 MOTOR:25HP |

| P RUBBER WHEEL DIAMETER: | ∮130 MOTOR:20HP |

| PROLLER WHEEL DIAMETER: | 110 |

| FEEDING POWER: | 5HP (VARIABLE SPEED FEED FATE.) |

| TABLE HOIST POWER: | 1/2HP |

| SANDING BELT SIZE: | 52” X 75” |

| SPIRAL CUTTING BLADE SIZE: | 15*15*2.5 MM |

| THICKNESS DIGITAL CONTROLLER / PRESSING USE PRESSING ROLLER | |

| PRESSURE SWITCH: WHEN COMPRESSED AIR IS INSUFFICIENT, MACHINE WILL AUTOMATICALLY STOP | |

| ANTI-KICBACK FINGERS: ANTI-KICKBACK FINGERS ARE BUILT IN FRONT OF SPIRAL CUTTERHEAD, ELIMINATION THE DANGER OF PANEL | |

| KICKBACK AND ENSURING THE IPERATOR | |

| PIANO-KEY TYPE INFEED PRESSURE JAWS: THE SPECIALLY DESIGNED PIANO-KEY TYPE INFEED | |

| PRESSURE JAWS ARE MOUNTED AT | |

| THE INFEED END. IT ASSURES SMOOTH FEEDING PERFORMANCE REGARDLESS OF WOOD THICKNESS VARIATION | |

| ANTI-EXPLOSION SWITCH: WHEN SANDING BELT IS BROKEN POWER OFF AUTO AND CONVEYOR WILL DOWN AUTO TO PROTECT CONVEYOR AND RUBBER ROLLER. | |

WIDE BELT SANDER

MADE IN TAIWAN

SPECIFICATIONS:

| MAX. WORKING WIDTH: | 16” |

| MIN. WORKING LENGTH: | 350 MM |

| MAX. WORKING HEIGHT: | 130 MM |

| MAIN MOTOR: | 7.5 HP |

| FEED MOTOR: | ½ HP |

| FEED SPEED: | 15/32.5 FPM |

| SANDING BELT SIZE: | 17” X 54” |

| NET WEIGHT: | 400 / 450 KGS |

| PACKING SIZE (LXWXH): | 965 X 965 X 1854 MM |

| Sanding belt tension is pneumatically controlled. | |

| Sanding belt oscillation is pneumatically operated. | |

| Air eye controls sanding belt tracking. | |

| Side extension bar provides firm support for large panels | |

| Additional infeed and outfeed rollers facilitate panel infeed. | |

| Pneumatically actuated brake provides instant stop. | |

| Automatic machine stop in case of power failure, for added safety. | |

| Body activated emergency stop bar provides safety guard for operator. | |

| Maunal elevation for conveyor table. | |